Transporting and managing materials

Regardless of the material type, different materials or products can be transported between different sources and sinks within the production environment.

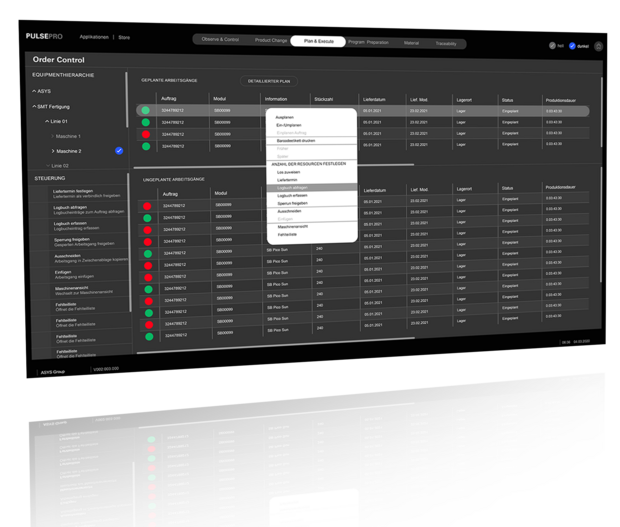

Planning of production orders

Our order planning still runs via Excel

Status

Manual adjustment via order progress

Solution

- Direct order control through „live“ planning of orders in production

- Recording of order progress in SMT and final assembly

- Connection of the machines or workstations via operator input (scanner)

Benefit

- Optimal transparency of current and planned order processing

- Clear presentation of orders and production times

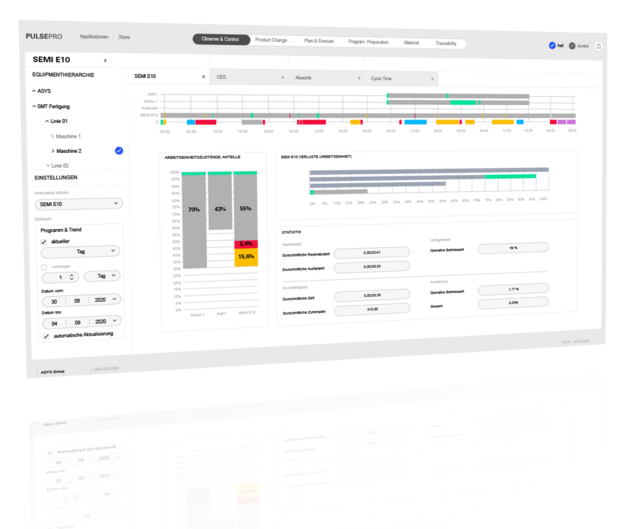

Statistical evaluation of your performance, errors and availability

Status

Manual statistical evaluation of production for the optimization of production processes

Solution

- Calculation and visualization of standard KPI values

- OEE / SEMI E10 / Target comparison of cycle times …

- Display of machine type dependent evaluations

- FPY / Drops / Assembled parts …

- Creation of customer-specific analysis reports possible

Benefit

- Increase of transparency, productivity and quality

- Cost reduction through support in process optimization

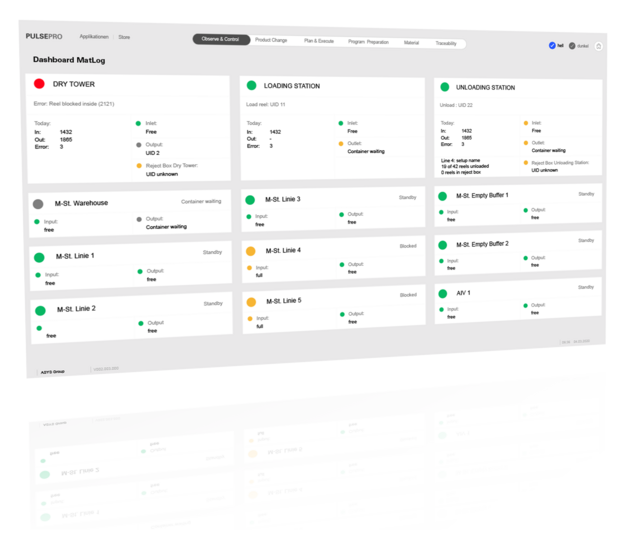

Live states of all machines

Display of current information

- Status / Errors

- Progress picking

- Transportation order

- Storage / Retrieval order

Simple statistical information

- Number of stored reels per day

Clear status display of all hardware components involved in the material flow

Trace your data / processes

Product Trace

- Recording the traceability data generated by the station

- Storage in internal database

Process Trace

- Acquisition and storage of process data per circuit board

- Display:

What process parameters were used to produce a circuit board?