Skip to main content

Skip to page footer

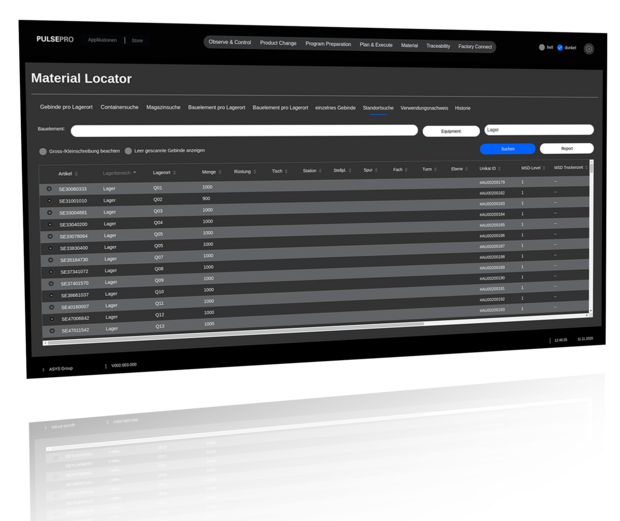

- Management of components (reels, trays) and printed circuit boards

- Component management based on Unique ID

- PCB management based on articles

- Management of paste/ consumables/ stencil

- Recording of storage/removal and remaining reel stock

- Support of pre-fitting area

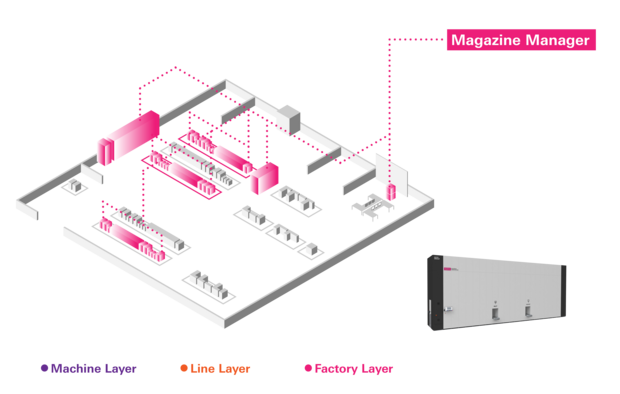

- Magazine management on UID basis (2D/RFID)

- Overview of quantities, location and states of all materials and transport devices on the entire shopfloor

- Moves empty / full magazines to the beginning of the line

- Picks up empty / full magazines from the end of the line

- Control based on work plan and order planning

- Autonomous magazine control

- Different outsourcing concepts

- Demand-oriented replenishment (PUSH)

- Pick up for complete order

- Support PULL concept

- Create picking list (automatic, manual)

- Operator guided (picking list) and/or fully automatic material supply (AIV)

- Checking the material availability

- Autonomous material replenishment for components

- Operator support for manual material replenishment

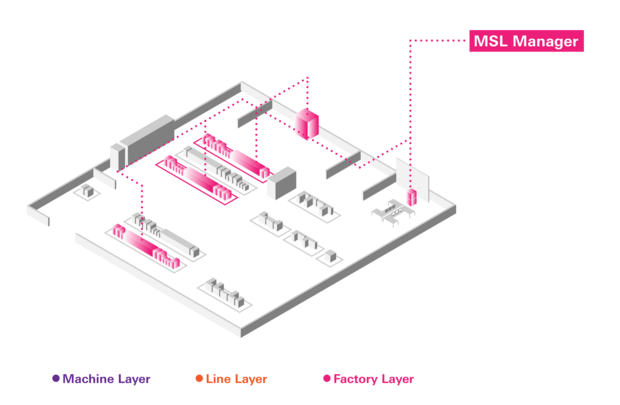

- Recording of MSL start/stop times

- Management in the DryTower

- Management in a centralized system

- Management via different storage locations/drying cabinets/ovens

- Locking of parts

- Monitoring the floor life time of moisture-sensitive components

- Management on different levels